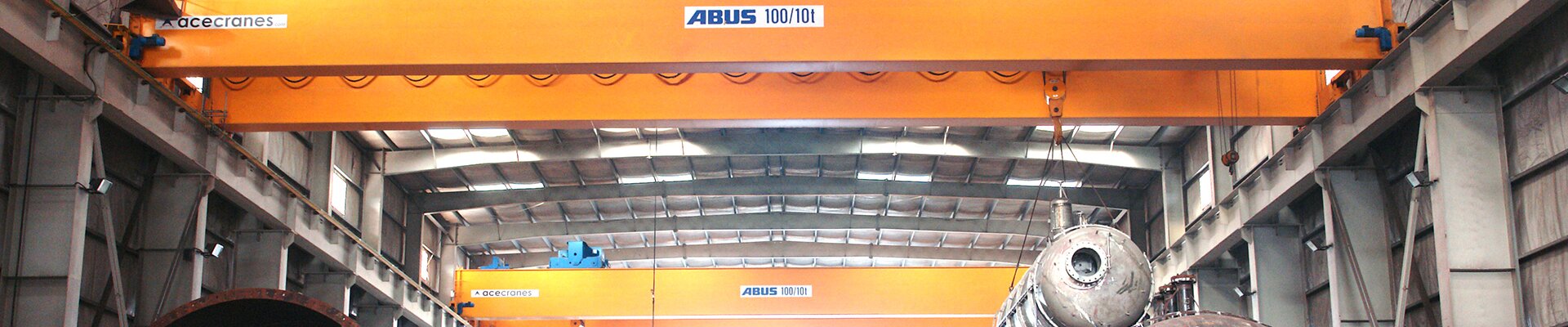

Two large ABUS cranes operating in the United Arab Emirates

Higher, larger, wider: the United Arab Emirates are the place where records go from strength to strength. One of the best known one would be the Burj al Arab, the luxury hotel in Dubai, which for many years held the record of being the highest of its kind worldwide.

But the industrial sector in the Emirates is also possibly record-breaking working at an all-time high to satisfy the requirements of infrastructure projects particularly in the oil and gas sectors, in the chemical and petrochemical industries, as well as the cement industry, and energy sectors.

A company hailing from Pakistan, DESCON Engineering HFZC (www.descon.com), has made its mark in the energy sector; today it is one of the biggest producers in the UAE. In 2006, DESCON built a new production site for boilers and heat exchangers in the Hamriyah free zone of the Sharjah Emirate. Units built to customers’ specifications reach total weights of up to 150 tonnes.

Another company also producing in the the free zone got involved right from the planning phase to develop a transport solution for the boilers and heat exchangers: the company ACE Cranes (www.acecranes.com), headquartered in Dubai and the distributor of the German company ABUS Kransysteme GmbH for the entire Gulf region. ACE Cranes has more than 30 years of experience in the crane and hoist sector. ACE Cranes advised to install two double girder cranes of the ZLK type with lifting capacities of 100 tonnes each instead of one single crane with a total lifting capacity of 150 tonnes. The material transport solution favoured by ACE Cranes with two cranes in tandem operation benefit the customer in two ways: DESCON not only enjoys higher flexibility when moving loads but it will also greatly decrease the costs for the building and the steel structures.

The hoists used were double-rail trolleys with twin hoists of the GM7000 Z type with a lifting capacity of 100 tonnes each. The eight-wheel cranes have also been fitted with smooth starting units AZS. The AZS serve to smooth acceleration and deceleration of cranes and hoists also when switching between fast and slow travelling modes. The AZS enable the crane operator to transport huge and delicate goods gently and safely. Auxiliary hoists with lifting capacities of 10 tonnes ensure that smaller and less heavy loads are transported without hassle too, i.e. not requiring specialised below the hook attachments that would be necessary for the hook of a 100 tonne hoist.

The cranes have been operating for four years now. A service contract with ACE Cranes includes preventative maintenance thus making for a minimum of downtime for the cranes.

Higher, larger, wider: These ABUS cranes with a total lifting capacity of 180 tonnes and spans of 27 metres at the DESCON Engineering plant are among the largest indoor cranes currently operating in the industry in the United Arab Emirates.