ABUS single girder EOT cranes at AMCO in Bremen

The company AMCO Metall-Service GmbH (www.amco-metall.de) with headquarters in Bremen in Germany was founded in 1980 and has since been engaged in the supply and the treatment of non-ferrous metal semi-finished products. 220 staff work for AMCO in the large warehouse and in the administration in Bremen as well as in several sales points throughout Germany. They cater for the individual requirements of the customers in the industrial and commercial sectors such as trade, metal construction and metal working, mechanical engineering and construction, as well as transport and building industries. For this the AMCO employees make use of a warehouse continually stocked with 5,000 tonnes of goods. This material, i.e. for example aluminium, brass, copper and bronze is then commissioned, cut and/or machined in accordance with customers’ specifications. An extensive range of machinery is used in processing the goods including well over 30 panel saws, pole saws, and other special saws. In addition, AMCO offers its customers a wide scope of processing options such as milling, sawing, making holes, sanding, drilling, punching of the materials as well as welding and mounting of complete components. Select partner companies of AMCO also offer coating the materials, for example anodising or powder-coating them, if requested.

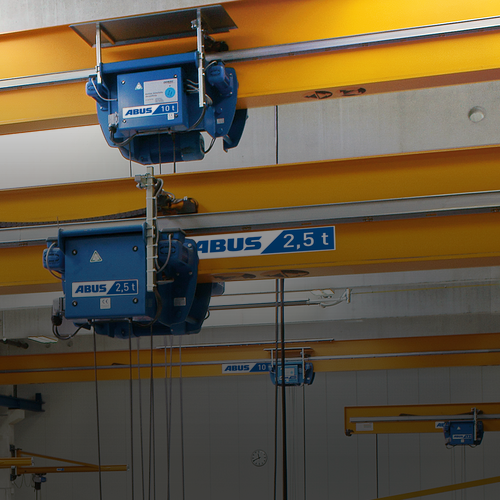

AMCO guarantee their customers the supply of the materials within the shortest possible time. This ambitious target of the AMCO staff is making high demands on planning and logistics and on the internal material flow of the goods. Every day about 500 commissions of the most diverse long materials weighing about 50 tonnes need to be moved. This requires speed yet has to be reliable as well as safe for the operators. For over 25 years now AMCO has been relying on the assistance offered by the ABUS representative Jochen Hochmuth and the ABUS crane solutions when it comes to material flow and individual solutions for each application. The most recent project required servicing continually two output stations of a high-bay storage for long material. As both stations need to be serviced simultaneously two single girder EOT cranes of the ELV type were installed with spans of 15.9 meters and load capacities of 2 x 2 tonnes. As these cranes are handling long materials they each have two identical monorail trolleys with allow the loads to be securely fixed using appropriate lifting tackle so that the loads do not swing or slip out of the lifting tackle. Using radio remote control to operate the cranes make it even safer for the loading personnel to use the cranes: the crane user surveys the whole loading area from a safe position and is thus able to move the loads without danger. Fast material handling is required in this particular application and both cranes use higher than normal speeds for lifting as well as for trolley travelling.

Speed and reliability were required for this material flow solution. Both requirements were satisfied also through the use of a special steel construction recommended by the ABUS representative. This steel construction makes it possible for the cranes to operate on different levels as both output stations of the high-bay storage are very close to each other. Another plus is the availability of the cranes as both cranes can service both stations. In the unlikely event that one crane should fail the other would be able to assume the task.

In total AMCO is now operating 25 ABUS cranes with different load capacities and spans. Management as well as crane users are completely satisfied with the ABUS crane solutions.